An Optimal Supply Chain Uses Both EDI & APIs

In the technology world, the rule has generally been that newer technology improves upon previous generations and replaces older technology. However, when it comes to integration technologies used to share data between partners in the supply chain, both electronic data interchange (EDI) and application programming interfaces (APIs) have their place—and will continue to co-exist for the foreseeable future. Smart organizations will figure out how to leverage the benefits of each.

Old school and newish school

EDI came onto the scene in the 1970s, and APIs followed three decades later. Both are well understood and widely used to the extent that each has its own place in the supply chain.

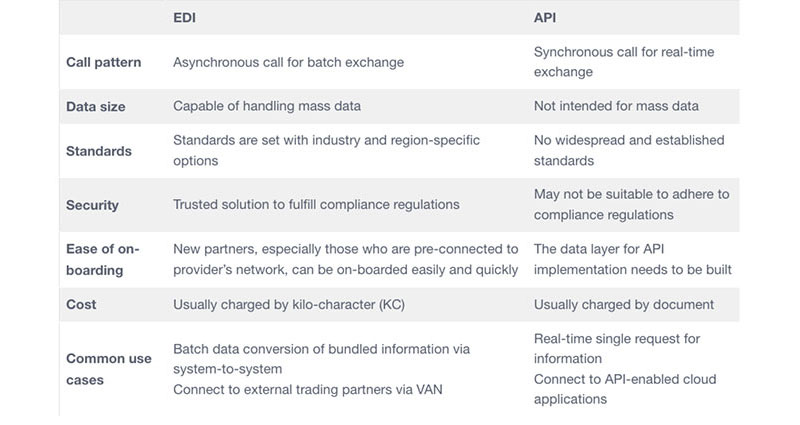

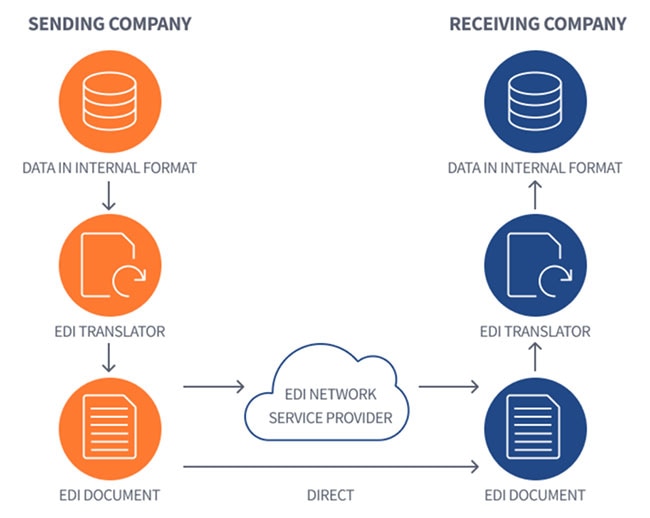

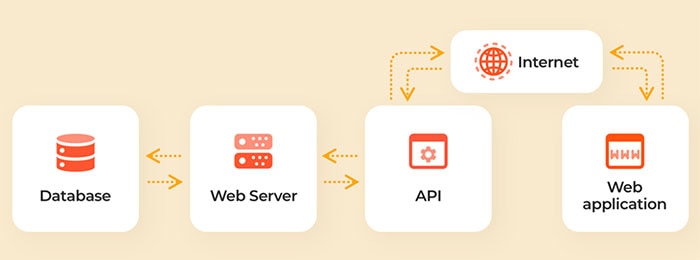

EDI is an easy and efficient way to pass large amounts of data between two similar systems (Figure 1), while cloud-based APIs take small amounts of data and exchange them in real-time between different systems (Figure 2). EDI standardizes data to allow for the translation of large numbers of physical documents (including purchase orders, shipment orders, status reports, invoices, etc.) into an electronic format. When real-time access to big data is the goal, APIs show a clear advantage. Further, APIs often remove the need for human intervention.

Figure 1: With EDI, the sending company connects directly to its partner using AS2 or another secure internet protocol, or through an EDI network provider, or a combination of both approaches, depending on how much data is being shared. (Image source: EDI Basics)

Figure 1: With EDI, the sending company connects directly to its partner using AS2 or another secure internet protocol, or through an EDI network provider, or a combination of both approaches, depending on how much data is being shared. (Image source: EDI Basics)

Figure 2: APIs comprise two main components; a specification that describes the details of the data exchange, and the interface that ensures communication between two applications. (Image source: Cleveroad.com)

Figure 2: APIs comprise two main components; a specification that describes the details of the data exchange, and the interface that ensures communication between two applications. (Image source: Cleveroad.com)

Weighing good and bad

Of course, how well a technology might deliver on business needs depends largely on how those needs are being defined. That means that some activities will be best supported by either EDI or APIs.

EDI offers a number of clear benefits:

- Excellent security and privacy: By transmitting over a secure connection, EDI ensures that trade secrets and confidential data are safeguarded. It is clear who has access to the data.

- Streamlining manual processing: EDI technology allows data to be collected and transmitted in a fraction of the time needed for older manual processes.

- Ubiquitous reach: EDI is an industry standard. Organizations will find that many others they wish to partner with already know and use the system.

Meanwhile, APIs also bring something to the party:

- Lightning speed: APIs don’t depend on physical documents being uploaded into a system. An API connects to systems and gathers and updates data as it becomes available. What takes hours with an EDI system might take only minutes using an API. Pickup requests can be automated which puts accurate information in the hands of people making projections.

- Easy: There is no need to customize the system to gather data—and the business partners don’t need to have matching versions in order to communicate since an API connects a variety of systems that are already in place, including transportation management systems (TMS), warehouse management systems (WMS), and enterprise resource planning (ERP).

- Future-proof technology: API technology can support new types of technologies as they emerge to further extend visibility along the supply chain. For example, APIs could connect to the blockchain-based systems that are quickly evolving as I write this.

At the same time, each of these technologies has its limitations. EDI can be expensive, both in terms of cost and time needed for training and integration. Also, it only creates an open channel between two parties. Further, both parties must use the same version (currently, there are three choices).

Meanwhile, the API approach doesn’t enjoy the same level of adoption as EDI. Its dependency on an Internet connection can be a problem in regions with poor, unstable infrastructure that can lead to outages.

At least for now, EDI and APIs work best as two halves of an approach to supply chain communication. By using both, organizations can capture the benefits of both file-based batch processes and real-time data sharing, while avoiding the downsides of both. For example, organizations may choose to use a different technology depending on what data is being transferred. Invoices, for example, can be secured and sent using EDI, while time-sensitive data like shipment status might be sent using an API. In the end, organizations may realize that they can get the best results by using both.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum